Processing technology

for the complete product portfolio

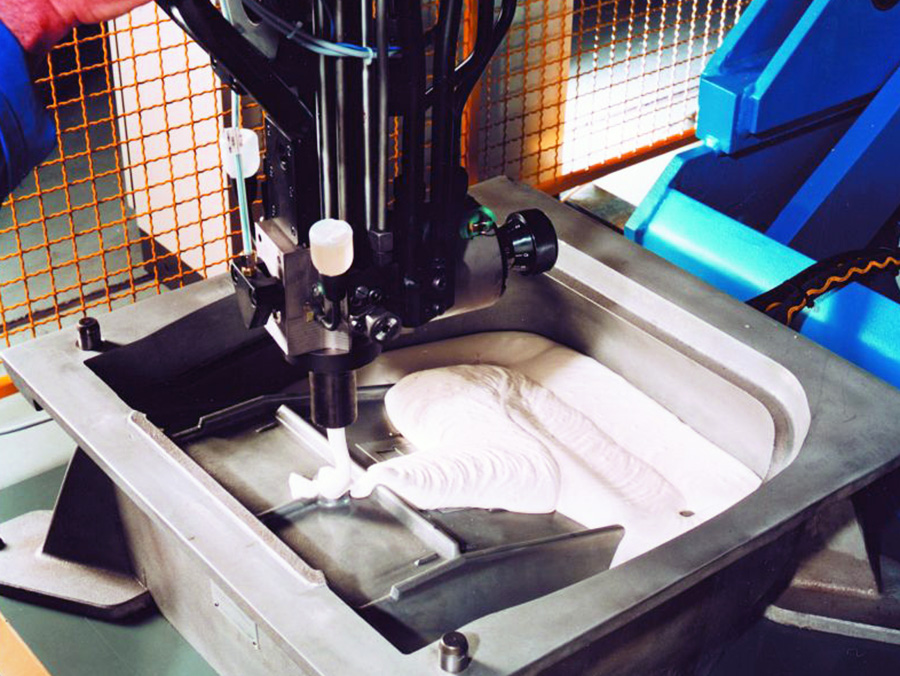

The way from the product idea to serial production is sometimes longer than expected: more than ever before the product development needs to be supported - by further development of the handling processes and corresponding samples or prototypes. Our experienced employees and our large machinery and technical facilities are at your disposal. Our machinery park is equipped with processing techniques for our complete product portfolio:

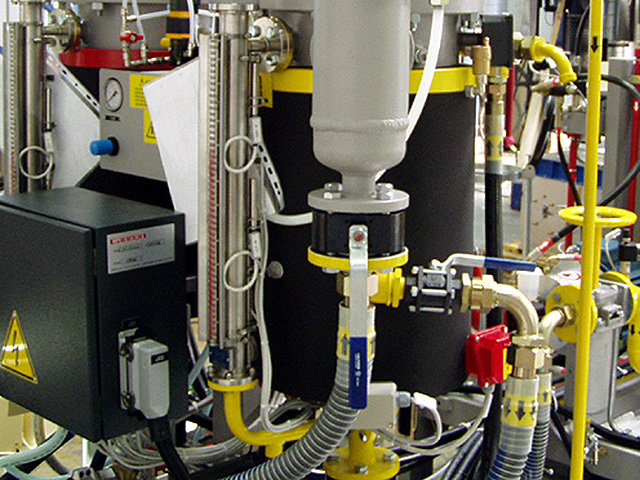

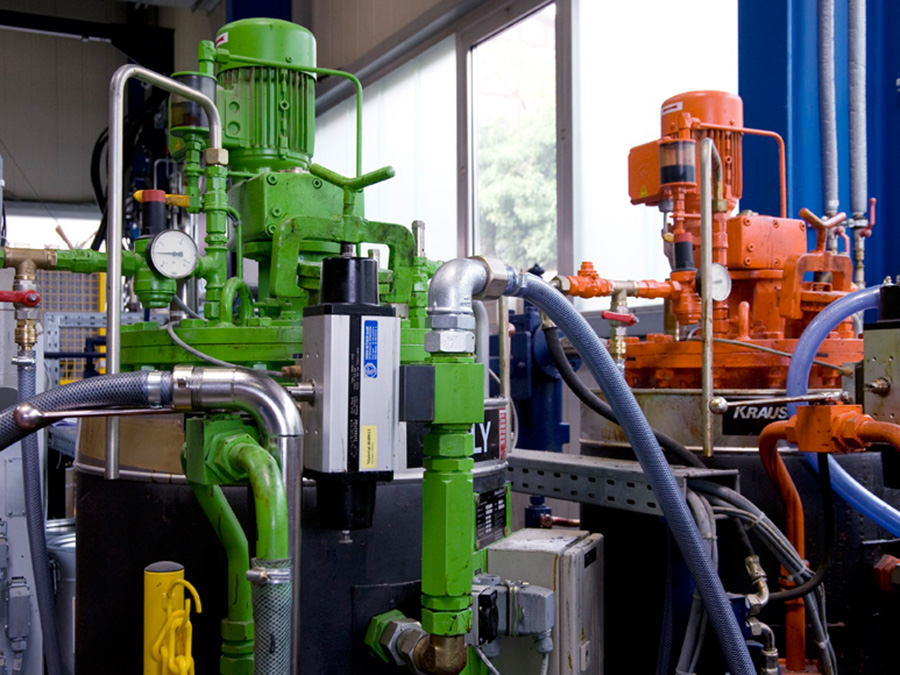

- Low-pressure machines for casting systems and PU elastomers

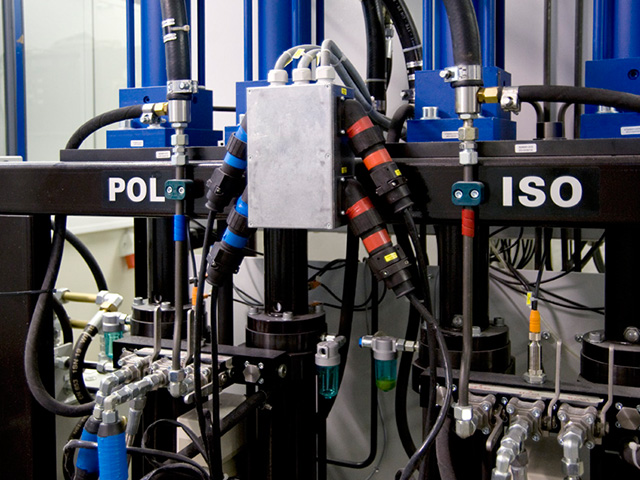

- High-pressure machines for foam, compact and spray applications

- Processing techniques for filled systems

- Centre for fibre reinforced solutions: LFI, spray technique, RTM

- Combination of injection moulding and PU high-pressure machine for integrated surface refinement (i.e. clearmelt/ColorForm)

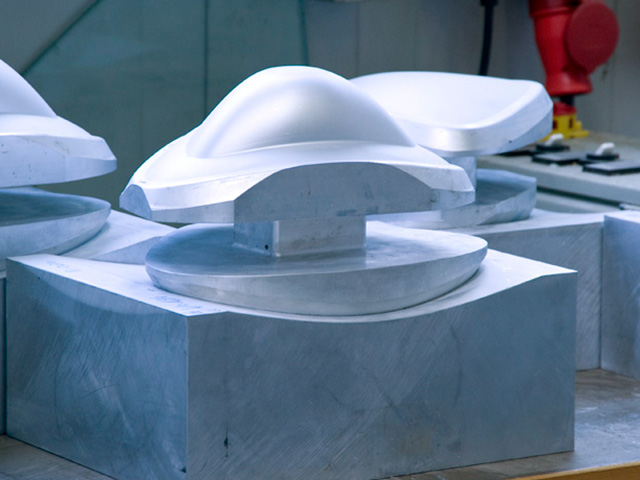

- Various mould carriers and experimental moulds

Together with you and by using our application engineering, we achieve economic success as fast and effective as possible. We consider ourselves as “extended workbench” and offer the following services in our purovation Center:

- Development of new technologies

- Optimizing support for products, processes and moulds

- Production of samples and prototypes

- Pilot productions, pre-series, small batches, covering of utilization peaks