PU high performance elastomers for special requirements

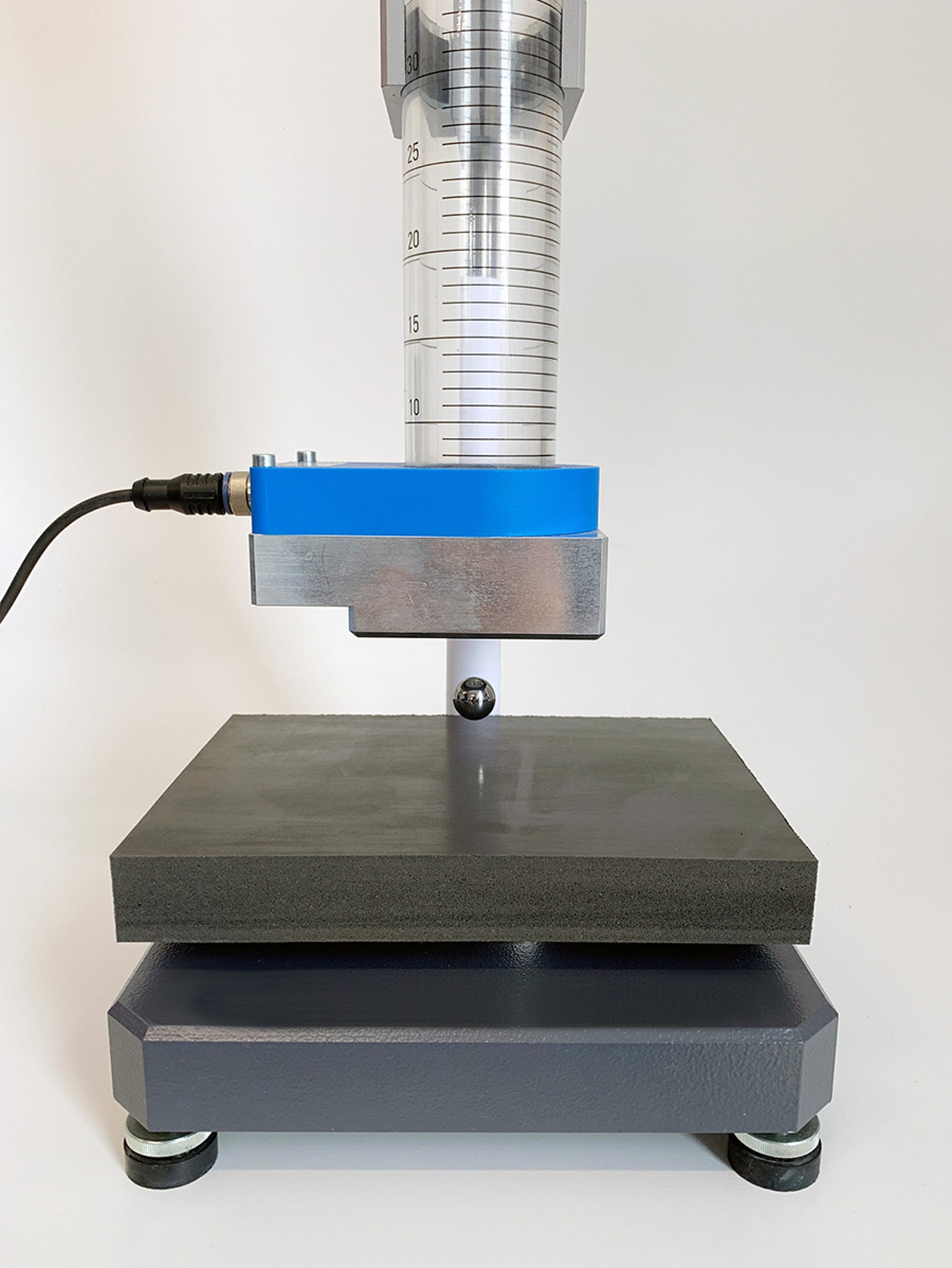

For many applications our polyurethane elastomers are an excellent alternative to rubber or other caoutchouc materials. purovib® withstands high pressures, solvents, chemicals, temperatures and mechanical shocks. It is characterized by good abrasion resistance as well as an outstanding resilience. Compared to other materials, purovib® components have an above-average service lifetime.

Density and elasticity can be flexibly adjusted: Thus, special characteristics can be designed in regards to vibration and sound isolation. For purovib®, the possible applications are as special and diverse as the characteristics: It can be used in the construction industry as well as for consumer goods such as acoustic decoupling of fitness machines. Far beyond the mere topic sound insulation - the application of purovib® elastomers is always inspired by special challenges.

- Guide bars

- High performance sealings

- Transport protection

- Formwork surfaces and matrices for moulded concrete components

- Sound insulation and shock absorption elements, i.e. footfall sound insulation

- Component density from 450-1050 kg/m³

- Excellent abrasion resistance

- High resistance to chemicals

- Very good elastic properties

- Hardness adjustable from Shore A 50 – 85

- Low and high pressure machines

- Open processing and component production in closed moulds

- Water-blown (foam systems)

- Processing temperatures from 35°- 60

- DIN 4102 B 2 and EN 13501-1 E