Efficient, high-quality surface refinement

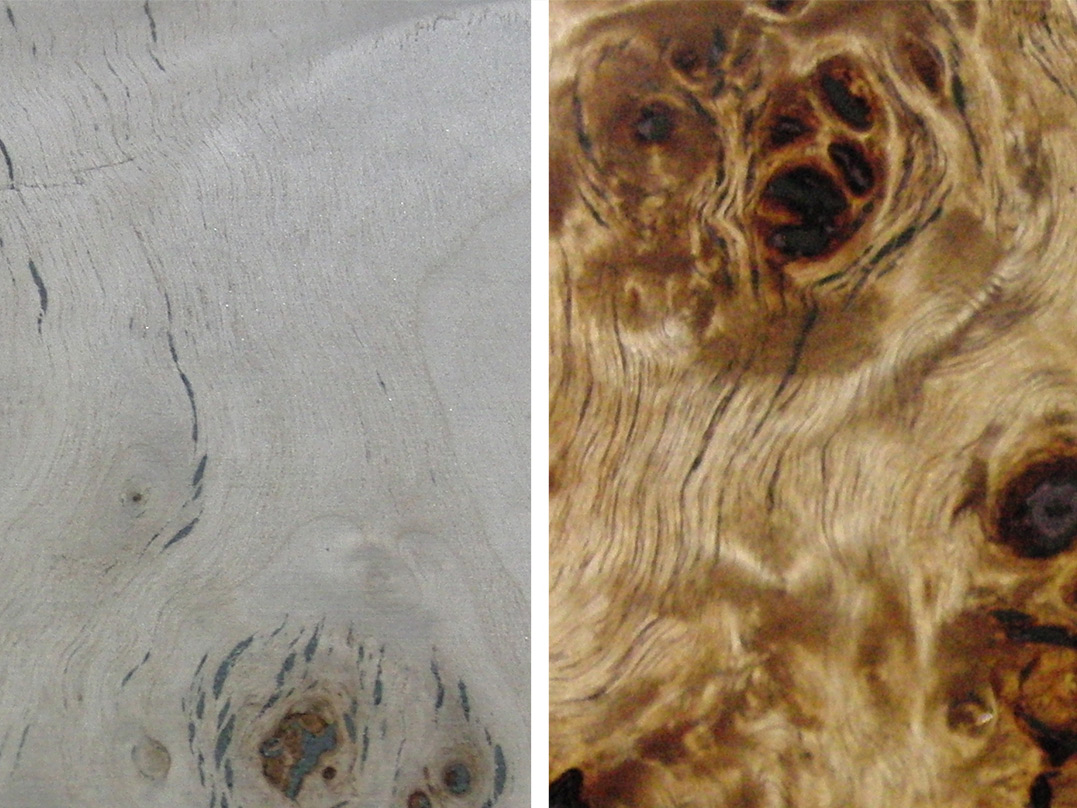

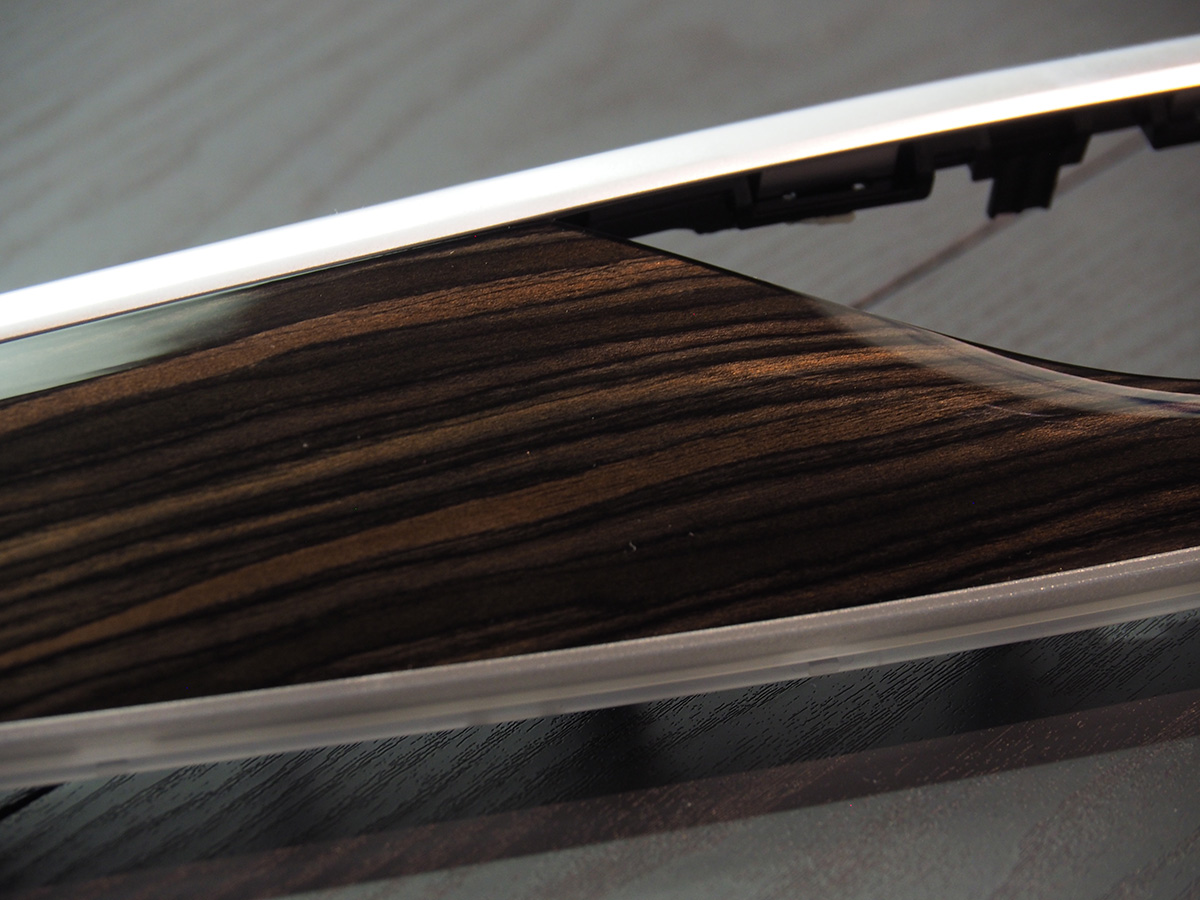

puroclear® products are used as casting materials for the tool-related refinement of wooden trim parts or thermoplastic parts – either for transparent or coloured coatings. The Casting materials are for example used in the automotive industry.

Advantages:

- UV-stability

- Easy processing / economic production, i.e. by self-releasing adjustment

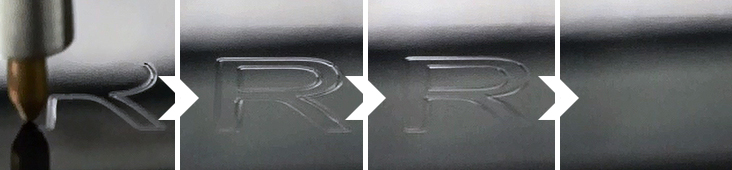

- High scratch resistance / self-healing effect / unique suitability for everyday use

- Custom-made differentiated surface solutions

- High gloss level and brilliant 3D effect

- Detailed impression of finest surface structures

- Combination of both

- transparent or coloured

- Production of functional, 3-D-touch or anti-reflective coatings possible

- Durable performance

- Proven in large scale production

- OEM approved

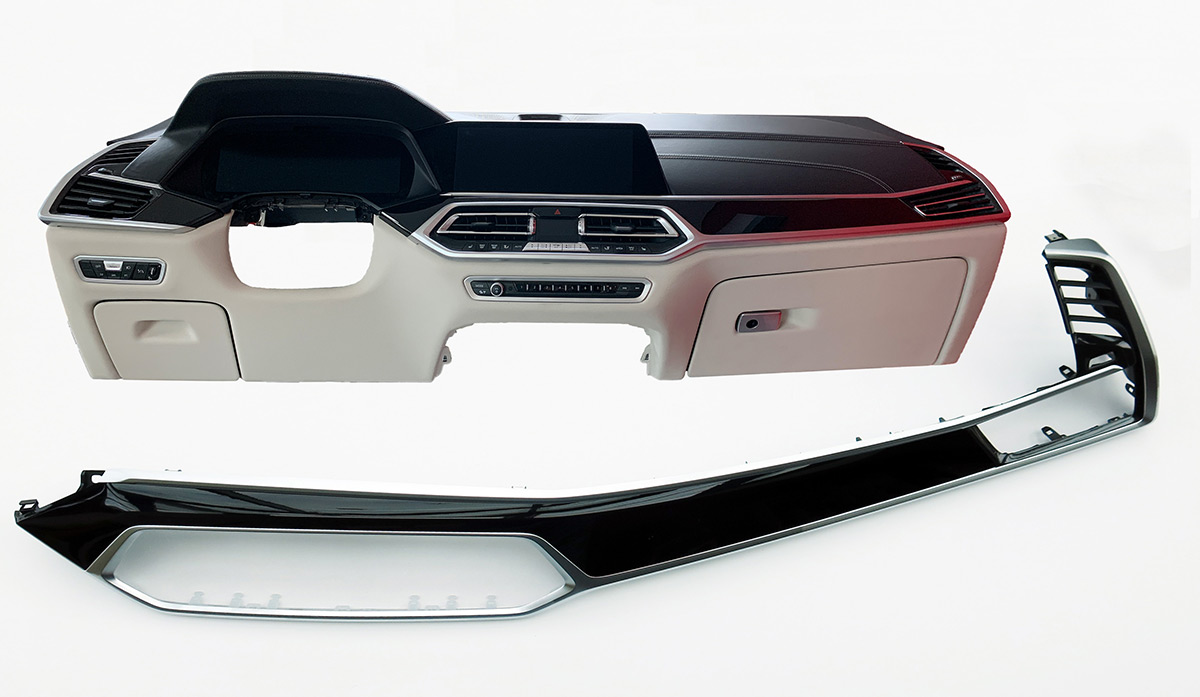

The combination of puroclear® with thermoplastic injection moulding is also very interesting: It is an efficient and low-emission alternative to cost-intensive painting to refine the surface of injection moulding components. Besides that, the high-quality surface coating scores by covering small defects of the substrate and by giving a brilliant 3D depth effect on your component. puroclear®.

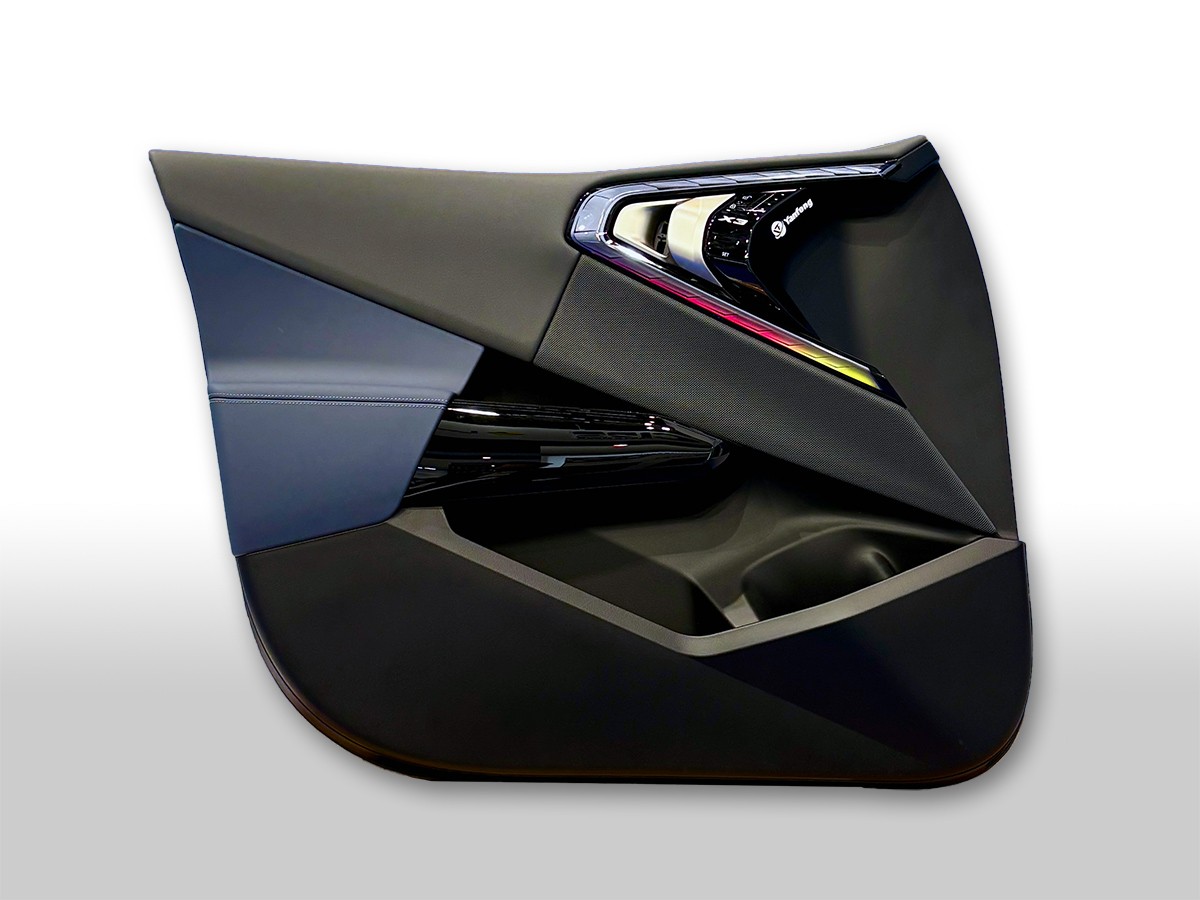

- Wooden trim parts in vehicle interiors

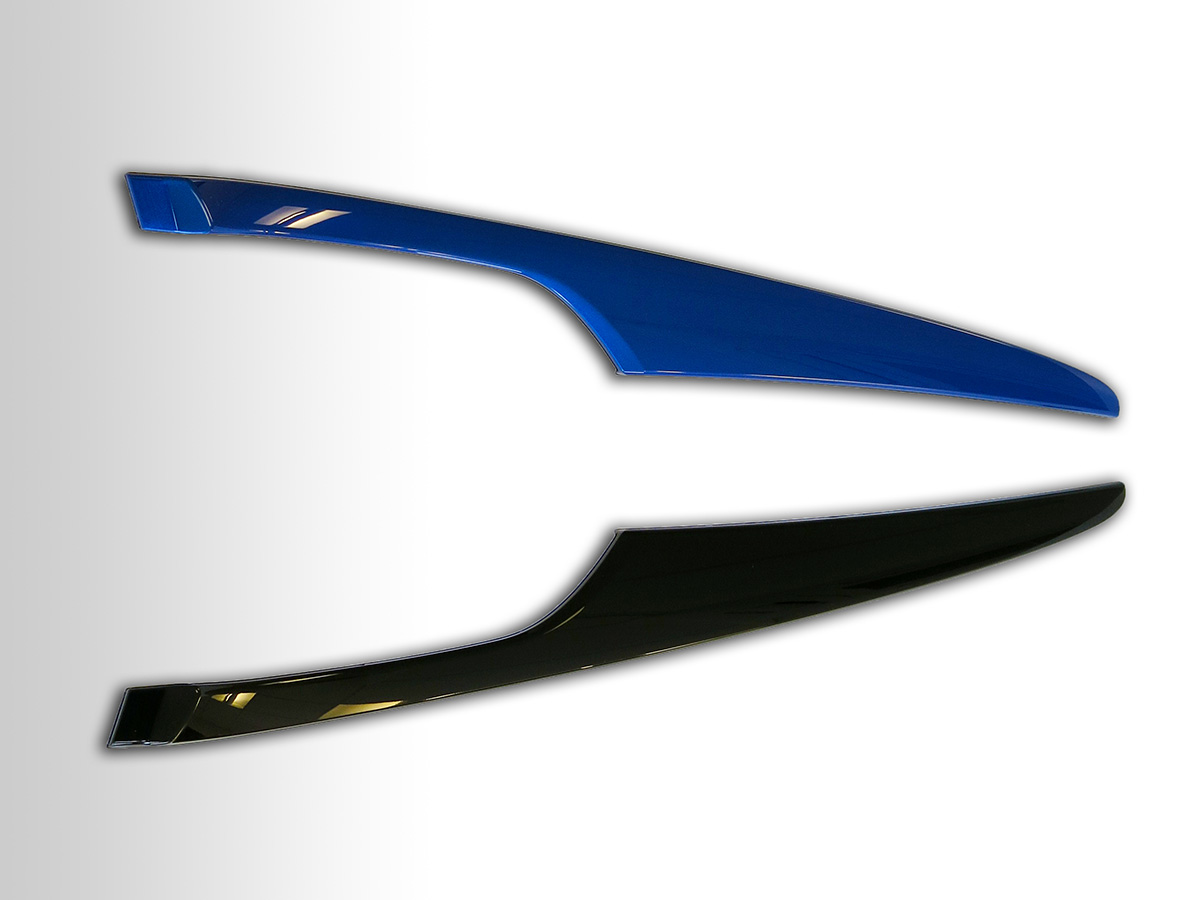

- Exterior applications (i.e. pillar panels of cars, front panels)

- Decorative and functional components

- Coating of composite components and other substrates

- Refinement of furniture components/tables

- Decorative elements

- ...

- Usability in CCM/CLEARRIM, ColorForm/clearmelt/DCDS Direct Coating and other technologies

- Hardness/haptics: from soft to hard (70 Shore A – 85 Shore D)

- Good adhesion to substrate, also with self-releasing adjustment

- Very good abrasion and scrub resistance

- System versions with self-healing effect

- Also at room temperature

- Scratch resistance acc. to Erichsen tested up to 20 N

- Complies with OEM specifications i.e.

- Sun simulation: 24h – DIN 75220-D-IN1-T

- Xenon weathering (artificial Florida and Arizona climate)

- Heat ageing

- Climatic cycle test

- Chemical resistance: sun cream, hand cream, bird droppings, tree resin etc.

- VOC/FOG: 70 ppm/125 ppm

- Cure time: 40–100 s (acc. to application and size of component)

- Transparent or (translucently) dyed coatings (i.e. piano-black)

- Coating possible of parts with thicknesses from 0,2 mm to 10 mm

puroclear® IT (= self releasing) is a system providing up to 1.500 demoulding processes without external release agent and thus enabling an almost off-tool production. Rework and scrap rate are significantly reduced. Impressions of high-glossy or rough surfaces with an impressive degree of repeatability are made possible.

puroclear®-systems with self-healing properties are hard coating materials characterized by an extraordinary suitability for everyday use. We adapt the self-healing effect according to your application.

Leatherlike haptics are possible with puroclear® in soft adjustment. They can be used as an alternative to puroskin® also for light colours.

puroclear® ECO – based on bio-based raw materials, these sustainable systems are comparable in performance to conventional variants. The systems contain 25% renewable carbon by weight and significantly reduce the PCF.

puroclear® COLOR – our systems in a colored version, either directly or via colour dosing in the mixing head. Nearly any variant is possible, whether plain or with effect finish, including colour matching.

puroclear® - self-healing effect