High strength – low weight

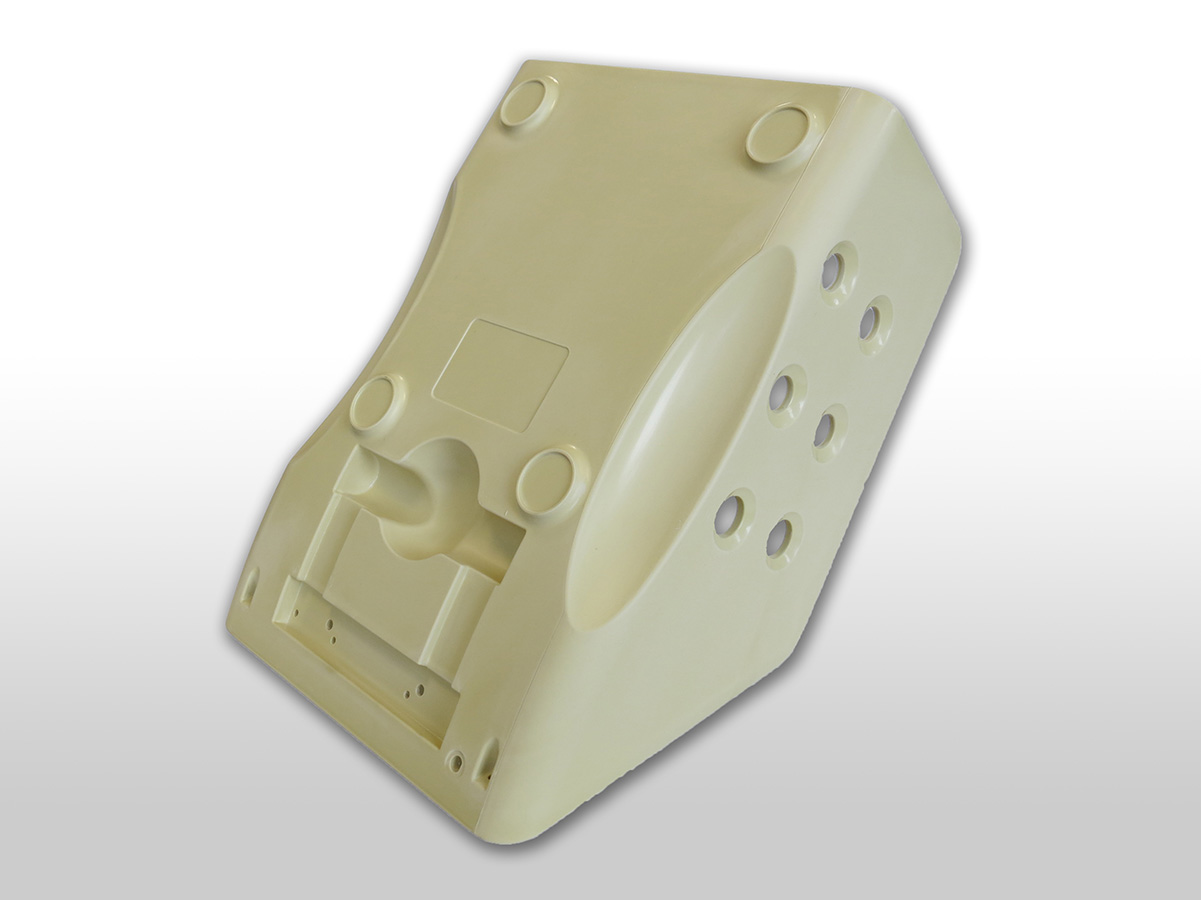

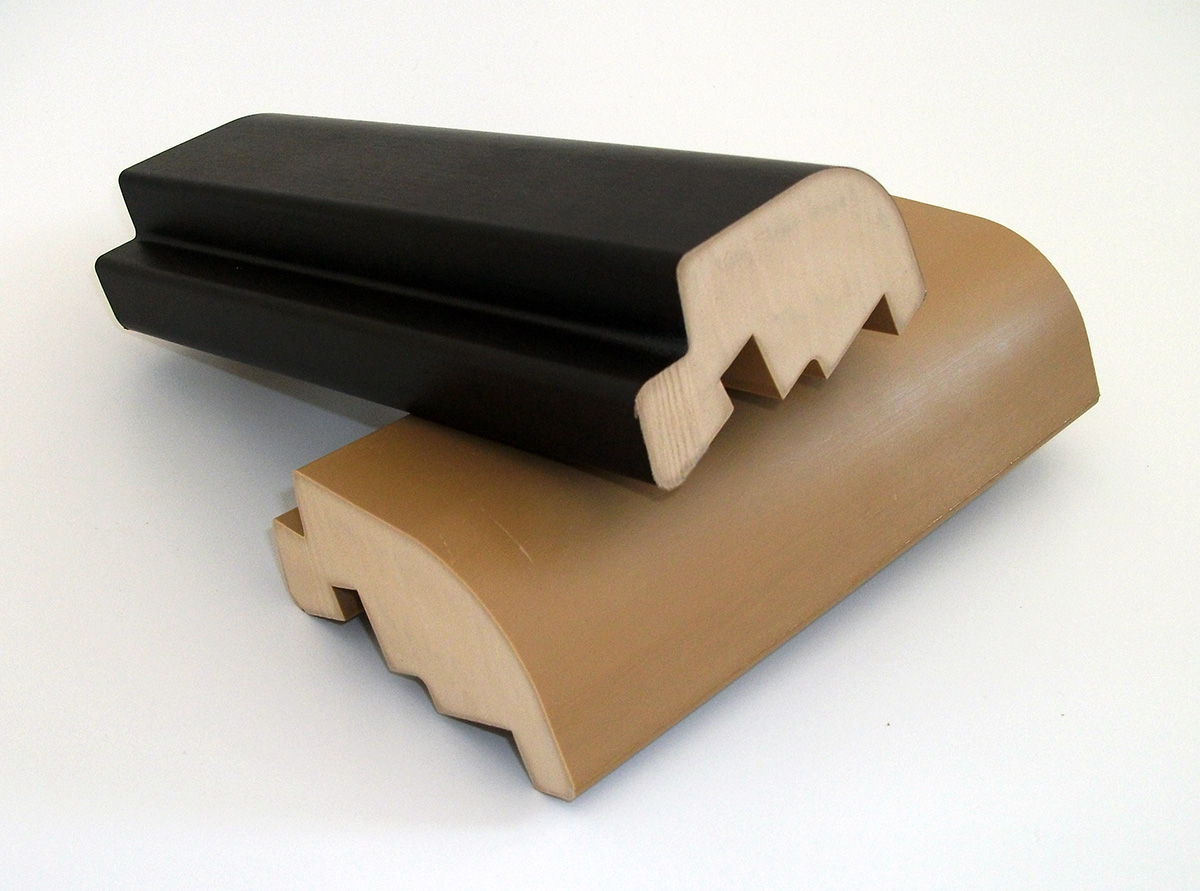

With our purodur® systems you can produce components with sandwich material structure in one step. The reaction mixture foams in the closed mould: Due to specific compression and temperature ratio it produces a foam core with fine pores and a massive edge zone. Density is integrally distributed in the component’s cross-section.

Depending on density, hardness adjustment and degree of compression different material properties can be achieved. This provides products from lightweight construction to structure functions to high-quality class A surfaces. Completely according to your requirements.

Applications

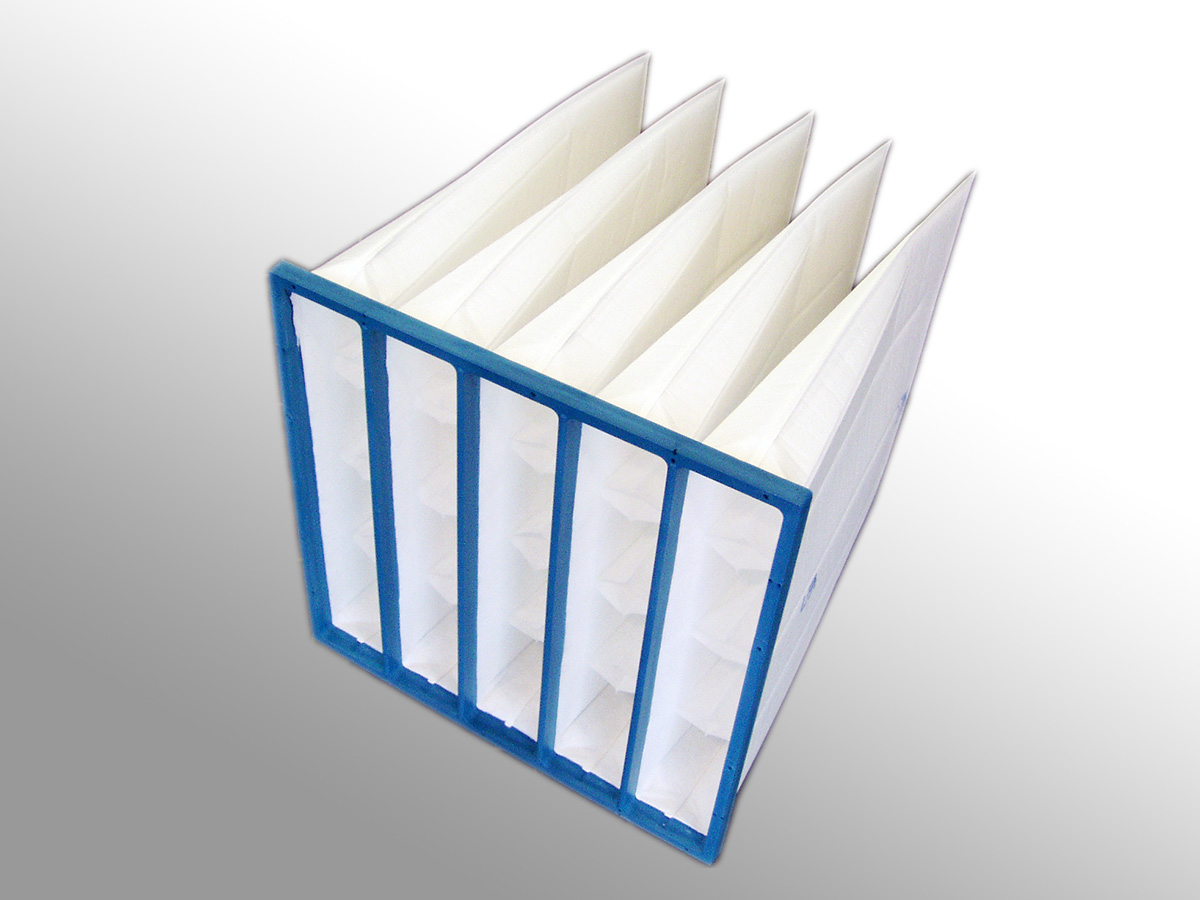

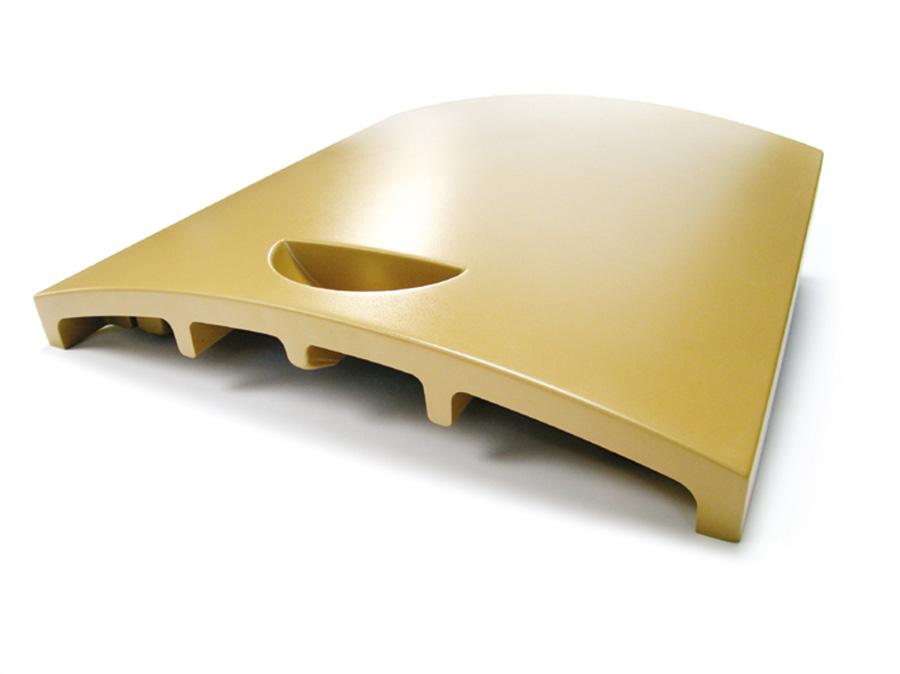

- Trim parts / housings / covers

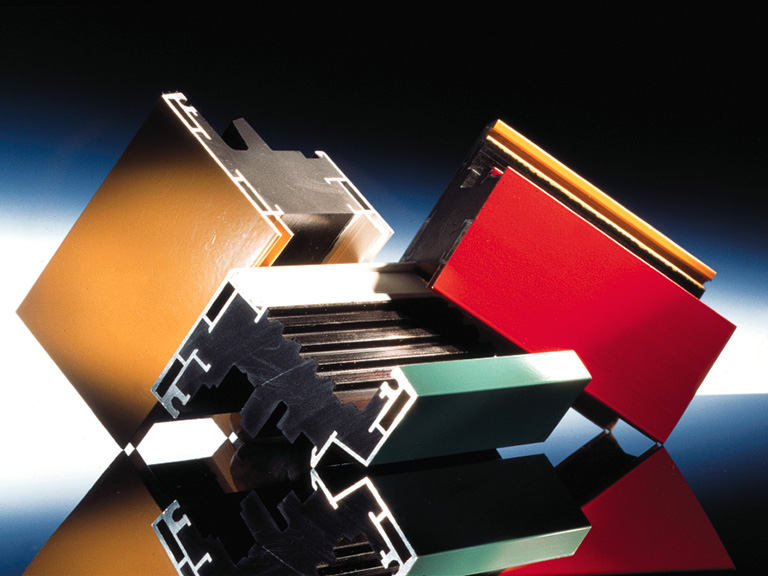

- High-quality heat-insulating energy-saving windows with high stiffness

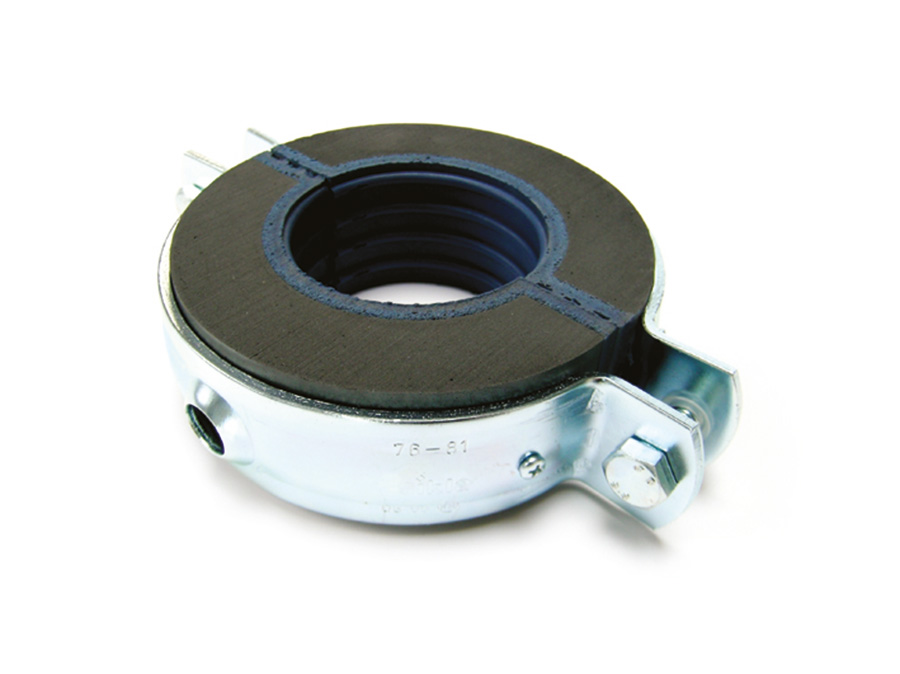

- Clamps and pipe supports

- Decor and furniture elements (stable in shape and extra light) for caravans and other camping cars

- construction bars

- ...

Typical properties

- Moulded part density of 220–900 kg/m³

- Shore D hardness of 35–85

- Tensile strength 3–16 N/mm²

- Blowing agents: mainly water, but also pentane and other physical blowing agents

Special formulations and versions

According to the field of application and production conditions, purodur® formulations can be tailored to certain properties:

- Maximal mechanical performance

- Good thermal insulation

- Self-releasing setting possible

- Good for painting and laminating

- Usage of bio and recycling polyols possible

Flame retardant formulations

- Electronic industry: UL 94 VO

- Rail vehicle construction: DIN 5510

- Construction industry: DIN 4102 B2, EN 13501 E