Compact material solutions for special applications

In some application areas a foam structure might be disadvantageous for the product performance. Compact PU systems, which react under exclusion of blowing agents can be used then - the purocast® product family.

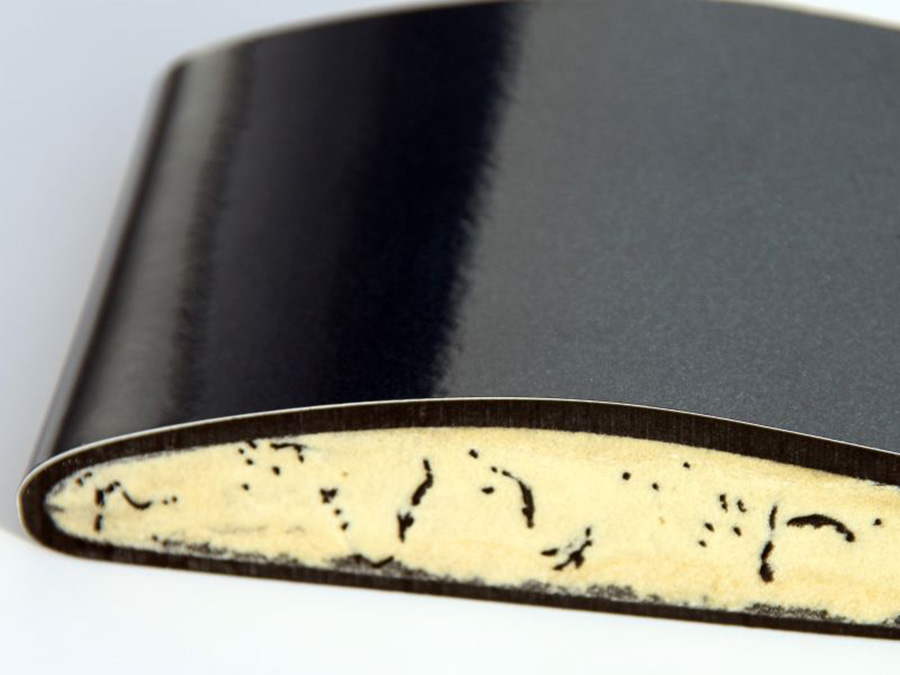

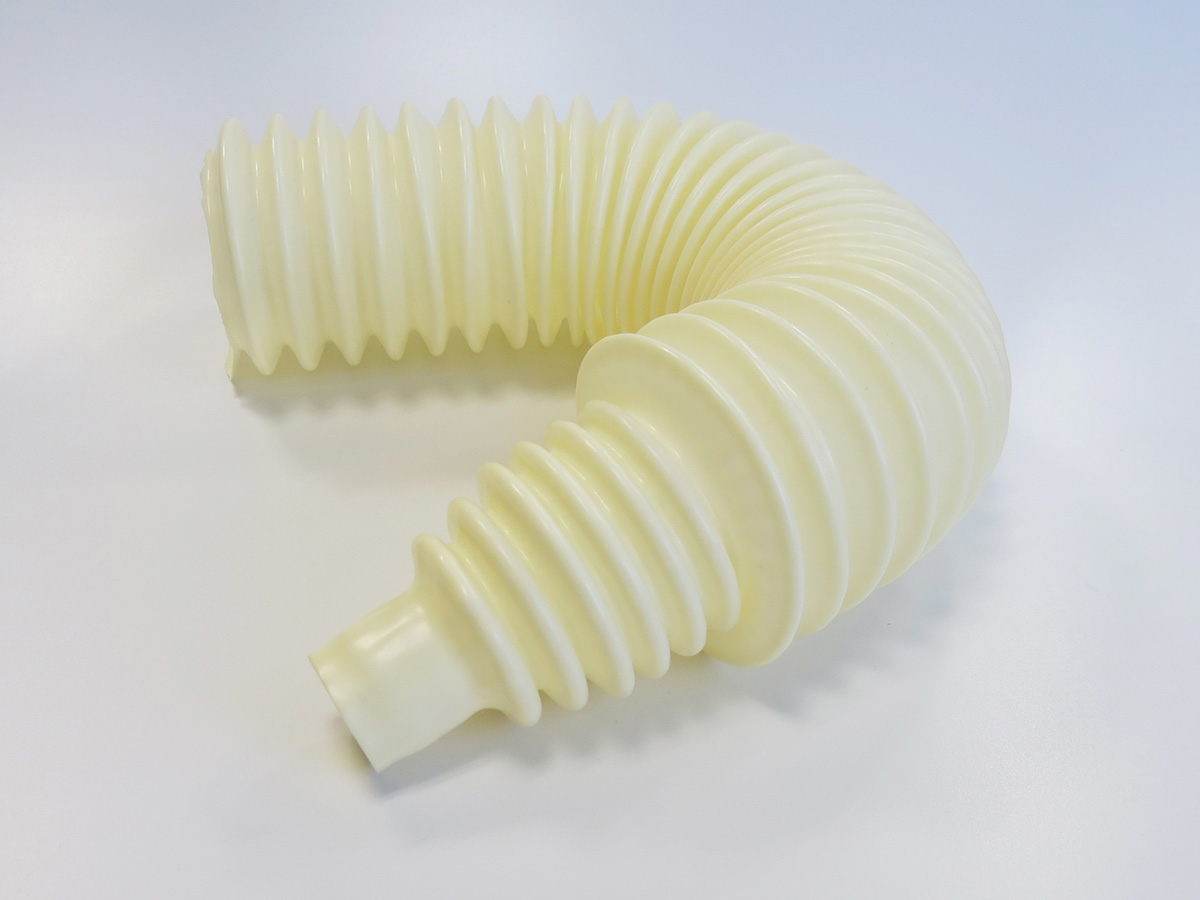

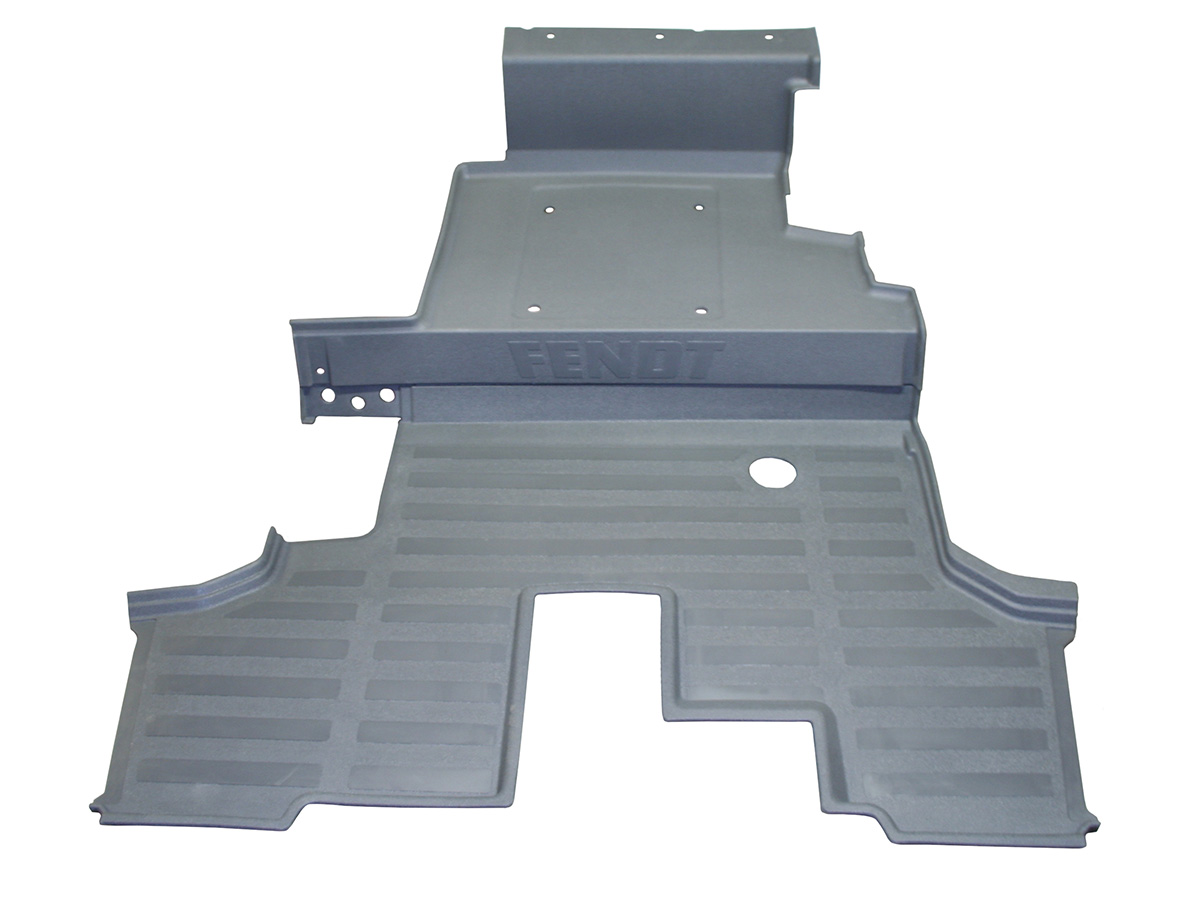

Such compact materials are ideal for very hard settings, i.e. in case of high impact stress or when high inherent stability is needed. Nonetheless, softer qualities can also be provided, i.e. to combine pleasant haptics with high abrasion resistance or to achieve high elasticity. Between hard and soft system formulations, we can adjust the properties of these non-foamed PU materials to your application.

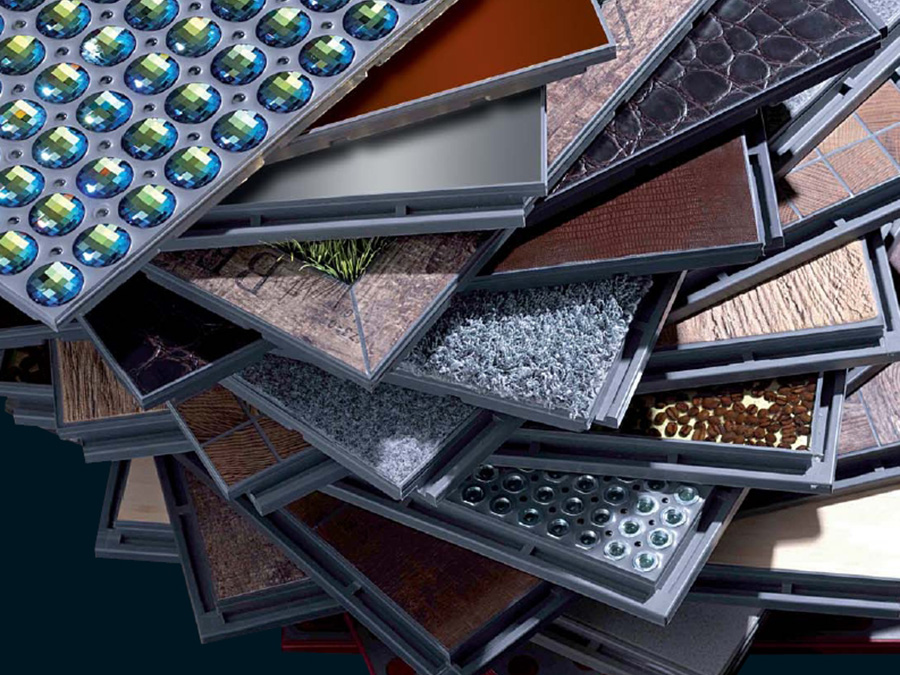

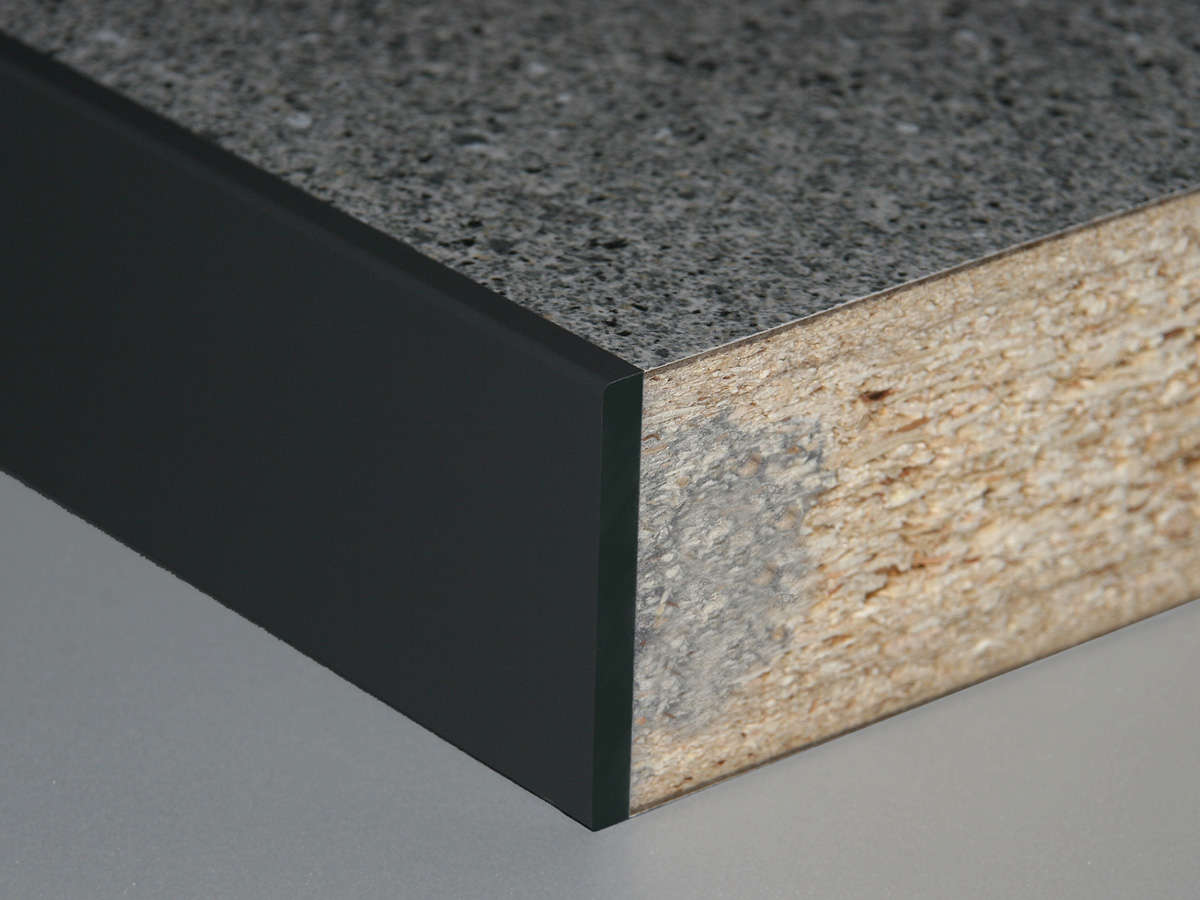

Do you set value on excellent surface characteristics regarding optics and/or robustness? purocast® polyurethanes serve a wide variety of cast and spray applications.

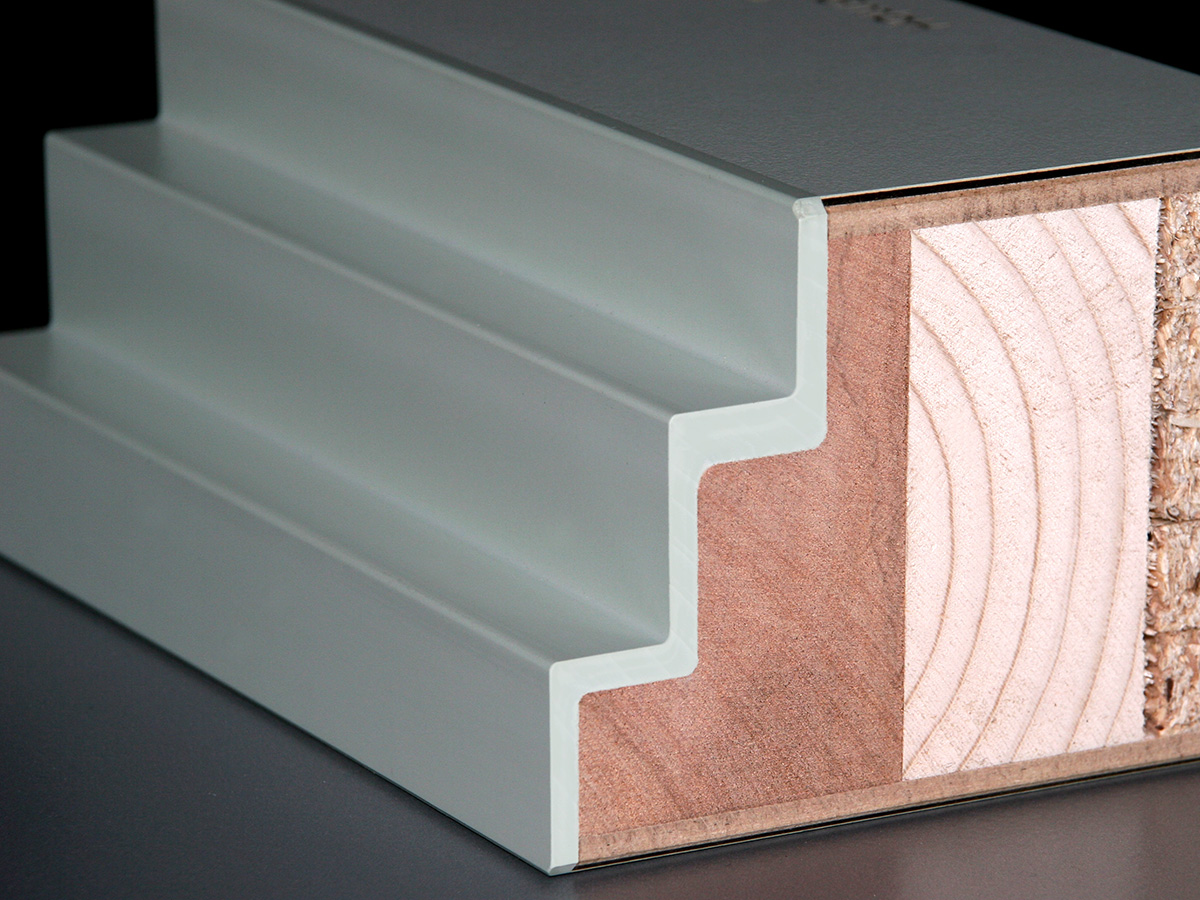

- Furniture / door edges

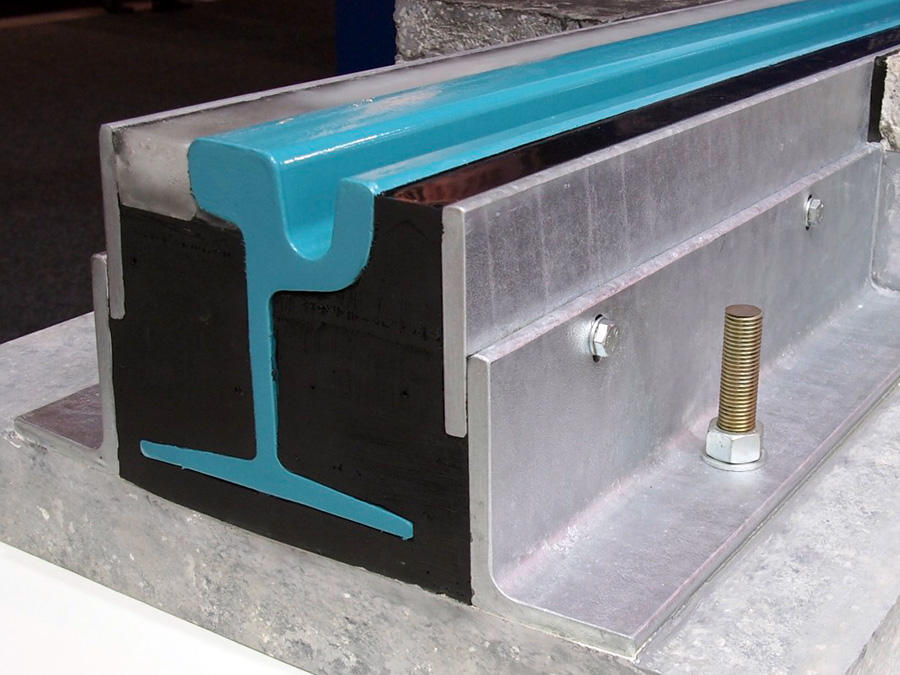

- Flooring systems

- Stairs

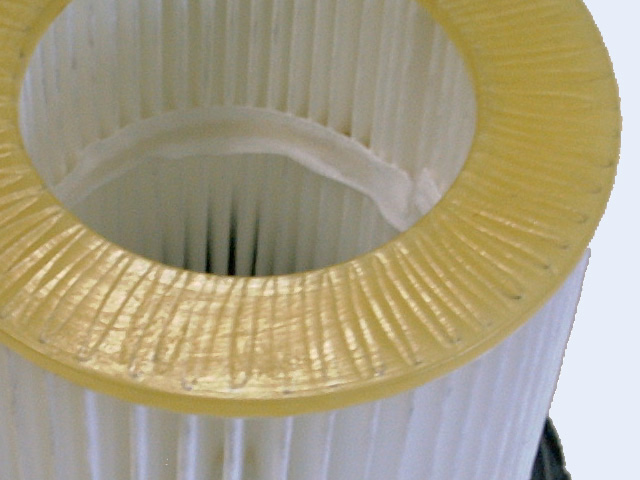

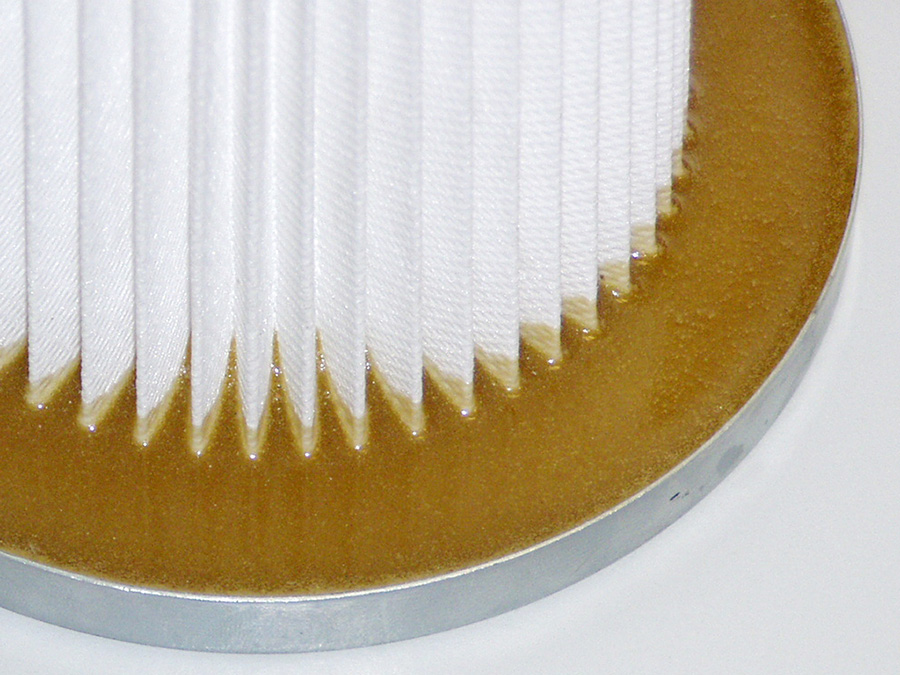

- Filter casting

- Electro casting

- Protectors

- Concrete formwork

- …

- Moulded part density of about 1000 kg/m³

- Hardness from shore A 10 to shore D 85

- Tensile strength 2–60 N/mm²

- FDA and foodstuff approval

- Anti-static

- Hydrophobic

- Impact resistant

- UV resistant, lightfast

- Sprayable – purospray®

- Automotive industry: FMVSS 302

- Rail vehicle construction: DIN 5510